Unlock the potential of your shale reservoirs

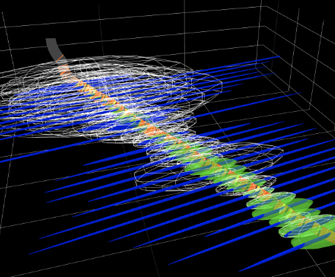

Seismos-FRAC™ utilizes a noninvasive method that delivers a direct, comprehensive measurement of fracture-network properties. Our approach uses a combination of ambient noise and induced, tube-wave pressure pulses to investigate the hydraulic fracture network. The measurements delivered include frac geometry (width, height and half-length, as well as near- and far-field characterizations of fracture network complexity, fracture conductivity and proppant placement. These results are produced on a stage-by-stage basis in near real-time. This enables the operator to review the measurements, assess the performance of a given stage and then apply learnings on successive stages.

Find out today how we can help you hear them Contact Us

Key AdvantagesAssuming a frac design was successful is one thing, but the value added from actually measuring the fracture system from the inside out can transform your designs and production. This is precisely what Seismos-FRAC™ brings to the table.

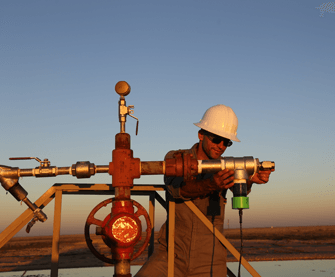

Non-intrusive, simple platform

Seismos-FRAC™ is mounted directly on the wellhead. There is zero operational downtime (or NPT) and takes less than an hour to install. The modular (plug & play) design allows for it to be instrumented on any well, allowing for it to be a seamless addition to your completion.

Real-time data deliverables

Data processing occurs at the field level with an end-of-stage report delivered within 30 minutes of the stage being completed. The real-time reporting enables clients to make on-the-fly decisions or changes that can optimize the future production of the well. Having this data in real-time gives our clients the tools and information they need to make key decisions without compromising time or manual effort.

Proprietary measurements

Seismos-FRAC™ is the only technology that utilizes acoustic energy from the surface to directly measure the fracture system. By sending and receiving signals, it measures the type (geometry wise) of fracture that was created. Our clients can rest assure that the data they receive is both unique to their operation and critical to fracture understanding

Case Studies:Seismos-FRAC™

Seismos-FRAC™