C&J Energy Services + Seismos: innovation through collaboration

January 1, 2019

A whole new level of reservoir intelligence.

This case study appeared in the January 2019 issue of E&P Magazine

Two cutting-edge technologies bring an unprecedented level of reservoir understanding to your shale operations. These affordable, noninvasive solutions deliver vast improvements in fracturing plans, field development and operational efficiency.

Oilfield innovation hasn't always come from research centers. In fact, some of our best efforts originate at the front lines. In the quest to solve everyday problems, operators often deliver groundbreaking results by combining two technologies in a new fashion just as George Mitchell did when he solved the shale puzzle by teaming the technologies of massive hydraulic fracturing and horizontal drilling.

Since those early days in the Barnett Shale, the industry has focused on improving operational efficiency

to drive costs down and maximize profitability. As the business matured, the incremental gains on operational efficiency began to level off. Today, this leaves operators looking elsewhere for the next game-changing innovation. Many believe it will come from a better understanding of the reservoir and are actively testing technologies that address this need.

Two such technologies are C&J Energy Services’ LateralSciences engineered completion method and Seismos' real-time hydraulic fracture monitoring. As standalone services, each excels at delivering a deep level of reservoir understanding in a very efficient manner. This makes both technologies particularly well suited to the shale business. The real value blossoms when they are used together.

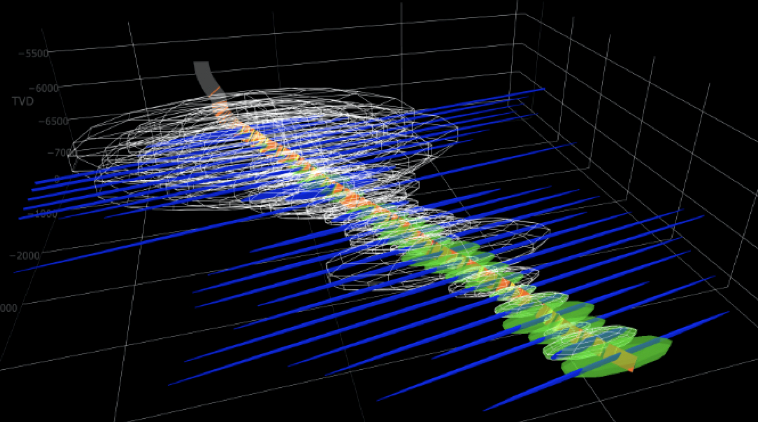

C&J Energy Services and Seismos deliver an unprecedented data array that provides insight into rock heterogeneity, fracture geometry and conductivity along the shale lateral.

C&J's LateralScience method uses common drilling data to optimize the well-completion design. The results are normally delivered prior to the completion and are used in a predictive manner to help build a treatment schedule that is most appropriate for the geomechanical properties of the reservoir rock being treated. The workflow is similar to those of other engineered completion technologies, but with added advantages. Because it uses existing drilling data to characterize the reservoir rock, it is noninvasive, and it is also an order of magnitude less expensive. This makes the LateralScience method ideally suited for the shale business.

New ParagraphThe Seismos technology uses borehole pressure-wave reflections to evaluate the properties of the hydraulic fracture network created during the completion process. The properties derived from these measurements include effective fracture half-length, fracture height and fracture width. The measurements also deliver additional properties, including the nearfield conductivity and complexity index, as well as a far-field conductivity and reservoir connectivity index. Their data analysis is based on proprietary signal processing that is done on-site during the fracturing process. The technique is non- invasive, since it is deployed using two surface-mounted pressure transducers, a transmitter and a receiver. Data processing is delivered in real time, which enables the operator to make decisions on the fly. The deliverables from this innovative technology are typically used to address challenges such as optimizing stimulation treatments, determining and improving diversion effectiveness, and predicting and avoiding communication with offset wells.

There are many significant advantages that can be achieved by partnering these two technologies:

1)

Used standalone, the LateralScience method pro vides valuable information about formation heterogeneity. Adding Seismos methodology to the equation enables the operator to visualize the geometry of the fracture network being created. This gives field engineers the ability to accurately predict fracture height growth in subsequent wells, which has a significant impact on fracture length and width. In short, the LateralScience method provides a qualitative indication of the lateral's geomechanical properties, and Seismos furthers the value by providing quantitative information to visualize the fracture propagation.

2)

Seismos' real-time fracture monitoring technology can benefit significantly from the LateralScience method, which provides valuable calibration data to accommodate the geomechanical variations across the lateral. For instance, a significant stage-to-stage change in the Seismos measurements might be due to a change in the interaction between the fracturing fluids and the lithology (i.e., acid and limestone) or perhaps because of a change in formation pressure due to depletion. By teaming Seismos with the LateralScience method, the rock-strength variable is eliminated.

3)

The effective fracture half-length information obtained from Seismos are valuable when "frac hits" are a concern. By monitoring the Seismos data in real time, operators can avoid the problem before it occurs. By teaming up with the LateralScience method, this can be done in more of a predictive manner, because the operator knows whether the likelihood of a frac hit is high before pumping a stage. Knowing the location of potential problem stages beforehand leads to more effective avoidance tactics.

4)

The same can be said for screenout avoidance. When engineers recognize the signatures on the Seismos and LateralScience products that correspond with screenouts, they can use the two together to avoid screenouts proactively. The LateralScience method lets operators know which stages to be wary of, and Seismos measurements provide information about how to quantitatively change the treating schedule to mitigate the issue.

The above examples are all focused on real-time completion engineering problems. However, some of the highest value propositions for the C&J/Seismos partnership come from the reservoir-engineering arena. When operators have access to the type of reservoir intelligence on every well in the field, they can make much better-informed decisions on well spacing. For example, if effective fracture half-lengths are 800 feet on the east side of the field and 1,800 feet on the west side, there is no reason to restrict the operation to a uniform well spacing. This understanding in variability across the field will enable maximum oil recovery –– while minimizing the danger of wells interfering with each other.

The shale business has built itself on industrialized processes that are predictable and repeatable, opting for efficiency and avoiding the "science projects." Often, deploying reservoir technologies is time intensive, so these processes can be detrimental to the efficiency of the operation. However, both C&J's and Seismos' respective solutions offer noninvasive technologies that can vastly improve completion performance without interrupting or delaying the schedule. It is important to note that it takes specialized expertise to properly apply the LateralScience and Seismos data to the perforating and hydraulic fracturing operations –– and C&J is well equipped to deliver optimal results. The partnership between C&J and Seismos is designed to create a "one-stop shop" that provides superior reservoir intelligence and then takes this a step further to ensure that the intelligence is leveraged properly to deliver maximum value to your operations.